Sika is known worldwide for developing cement grinding aids and additives for the optimization of cement production, product quality and performance, as well as minimizing the energy and resources required. SikaGrind® technology gives commercial benefits with less environmental impact while improving cement application. Our expertise in cement production allows expanding the capacity of cement plants.

Explore our Product Range

Why Grinding Aids Are Necessary in Cement Production

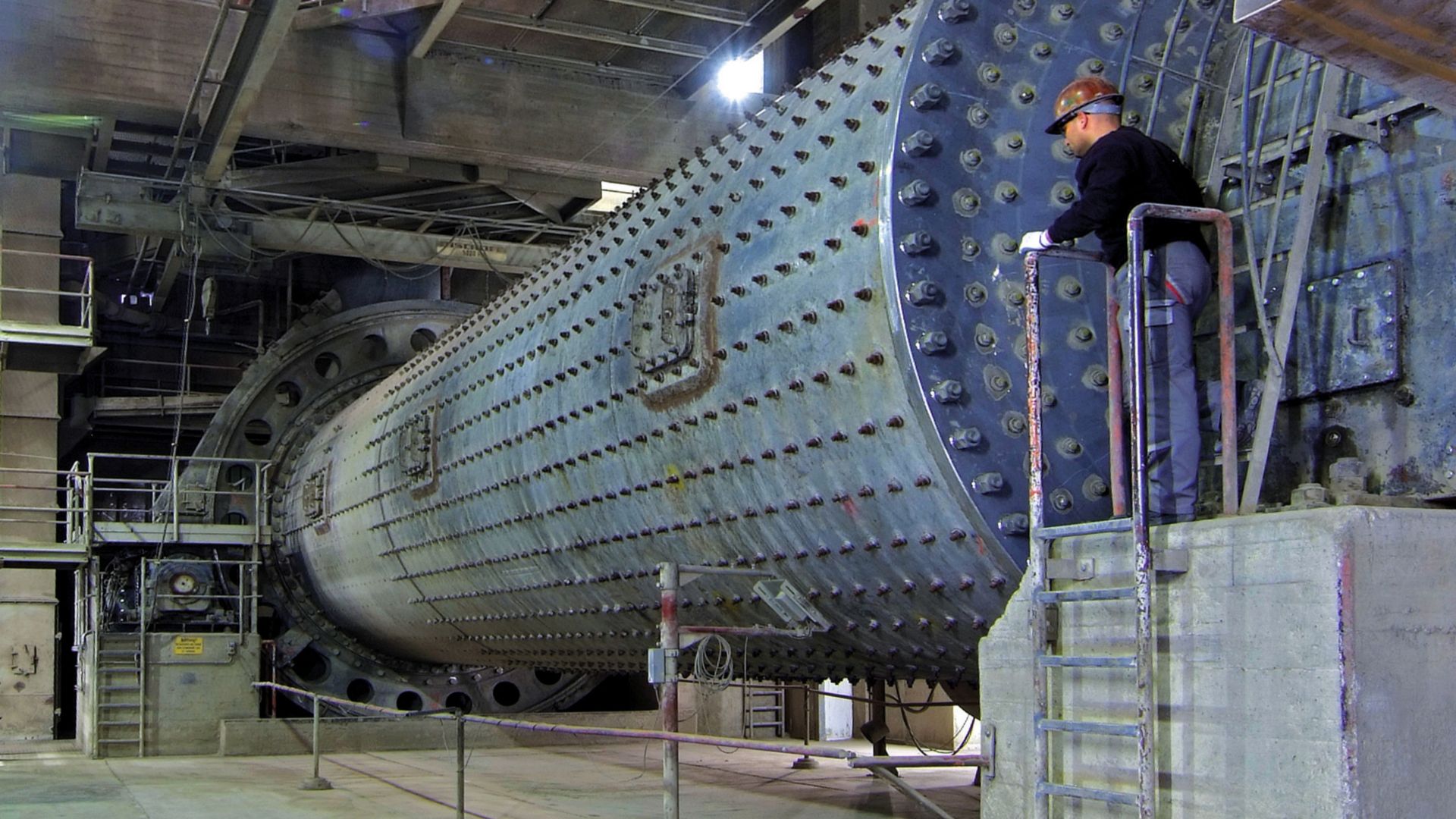

Finely ground particles are attracted together forming agglomerates and release energy (agglomeration energy). These attraction forces are also the reason ground particles stick on the insides of the mill (coating effect), which softens the impact of grinding media. Agglomerates of sufficiently ground particles are detected by the separator as coarse particles and consequently return as reject to the mill. Grinding aids are added at low dosages, typically in the range of 0.02 – 0.05%, to the mill feed or directly into the mill itself. Grinding aids reduce or even neutralize the surface energy by shielding the polarity to different degrees. Therefore, the particles do not attract each other anymore and the production process is optimized.

The Effect of Grinding Aids

- They ensure that the particles stay separated. This enables fine ground particles to leave the mill, creating space for more

coarse particles to be refined. - Using grinding aids reduces the particle coating effect and leads to cleaner internal surfaces in the mill. This intensifies the crushing impact and friction for coarse material between the steel balls, what finally reflects a higher grinding efficiency.

- Particles treated with grinding aids are better dispersed when they enter the separator. The higher the powder dispersion, the greater the probability that the particles are detected faster.